Marble processing, an ancient art, has undergone a radical transformation with the introduction of advanced technologies. These innovations not only enhance the quality and precision of final products but also optimize production processes, making the marble industry more efficient and sustainable. In this article, we will explore the most innovative technologies used in marble processing and their impact on the sector.

1. CNC in Marble Processing: Precision and Flexibility

CNC technology has revolutionized marble processing, enabling unprecedented levels of precision. Numerical control machines use advanced software to guide cutting and shaping processes, allowing for the creation of complex forms and intricate details. This approach significantly reduces waste and improves production efficiency.

Custom Designs with CNC

Thanks to the flexibility of CNC in marble processing, designers can create custom projects without the limitations of traditional techniques. Clients can request unique pieces, such as countertops and cladding, tailored to their specific needs.

2. Waterjet Cutting: Innovation in Marble Processing

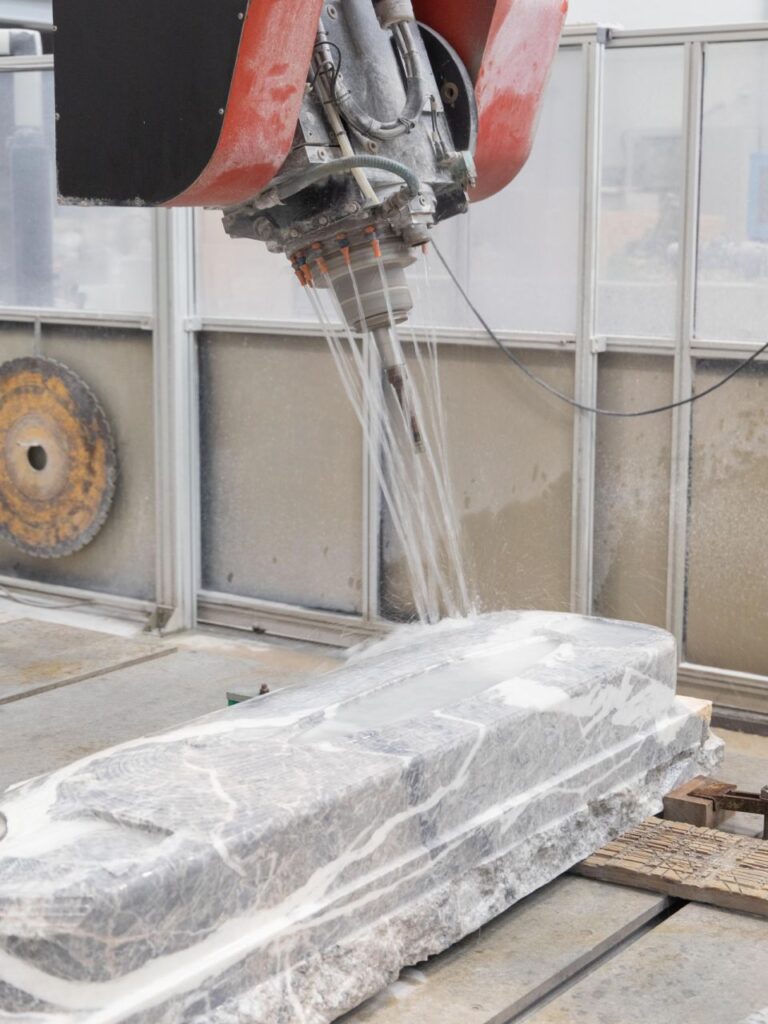

Waterjet cutting is an innovative method that uses high-pressure water jets to cut marble, offering numerous advantages:

- Less Heat: Generates less heat compared to traditional methods, reducing the risk of material cracking.

- Dust Reduction: Produces fewer dust and residues, contributing to a safer and cleaner work environment.

Versatility of Waterjet Cutting

This technology is highly versatile and can be used on various materials, including hard stones, glass, and metal, making it ideal for workshops with diverse processing needs.

3. 3D Modeling: Prototyping and Design in Marble Processing

3D modeling has become essential in marble design. Using advanced software, designers can create three-dimensional models, visualizing the project before production. This technology reduces the risk of errors and improves communication between designers and clients.

4. Management and Monitoring Software in Marble Processing

In addition to machinery, management software plays a crucial role in modernizing the marble industry. Advanced tools allow for monitoring and managing the entire production process, from extraction to processing, optimizing resources and improving overall efficiency.

Data Analysis for Optimizing Marble Processing

Monitoring systems collect and analyze real-time data, providing valuable insights into machine performance and resource usage. This analysis helps companies make informed decisions and continuously improve processes.

The Future of Advanced Technologies in Marble Processing

Advanced technologies in marble processing are opening new frontiers, combining precision, efficiency, and sustainability. The adoption of technologies such as CNC, waterjet cutting, 3D modeling, and robotics enables the creation of unique and personalized works of art while reducing environmental impact.

If you would like to learn more about how O&G Raimondi in Marnate utilizes these advanced technologies in marble processing, contact us. Our expertise and commitment to innovation can help you realize extraordinary projects that enhance the beauty and quality of marble.